NevoLine Upstream Platform

Evolving biomanufacturing technology

The NevoLine™ Upstream platform is an innovative biomanufacturing technology that delivers cost-effective viral production. This new generation platform builds on the successful NevoLine™ sIPV proof-of-concept designed to deliver affordable inactivated polio vaccine.

The high-performance, intensified platform features a flexible design to accommodate viral vaccine, gene therapy, and oncolytic virus production. With the NevoLine™ Upstream platform, automated GMP clinical and commercial-scale upstream production is achieved within a 3 m² footprint.

Scale-X™ cell collect

Seed train made simple

The scale-X™ cell collect module is a benchtop cell harvest system for fixed bed to fixed bed inoculation. The module retrieves cells through a combination of enzymatic and mechanical action, providing high cell harvest yields (up to 2.1E+09 cells/m²) with excellent viability (>90%). This enables cost-effective cell expansion in GMP-compliant conditions, while de-risking the seed train process in a low footprint.

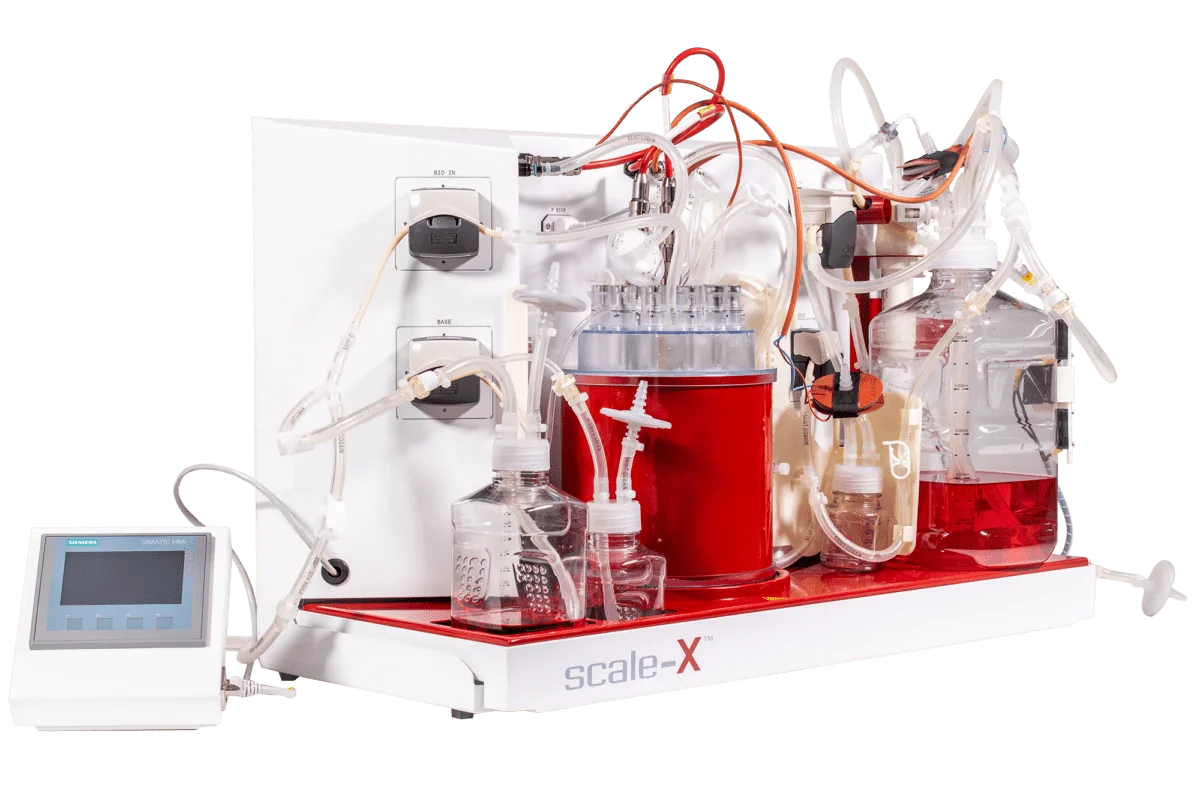

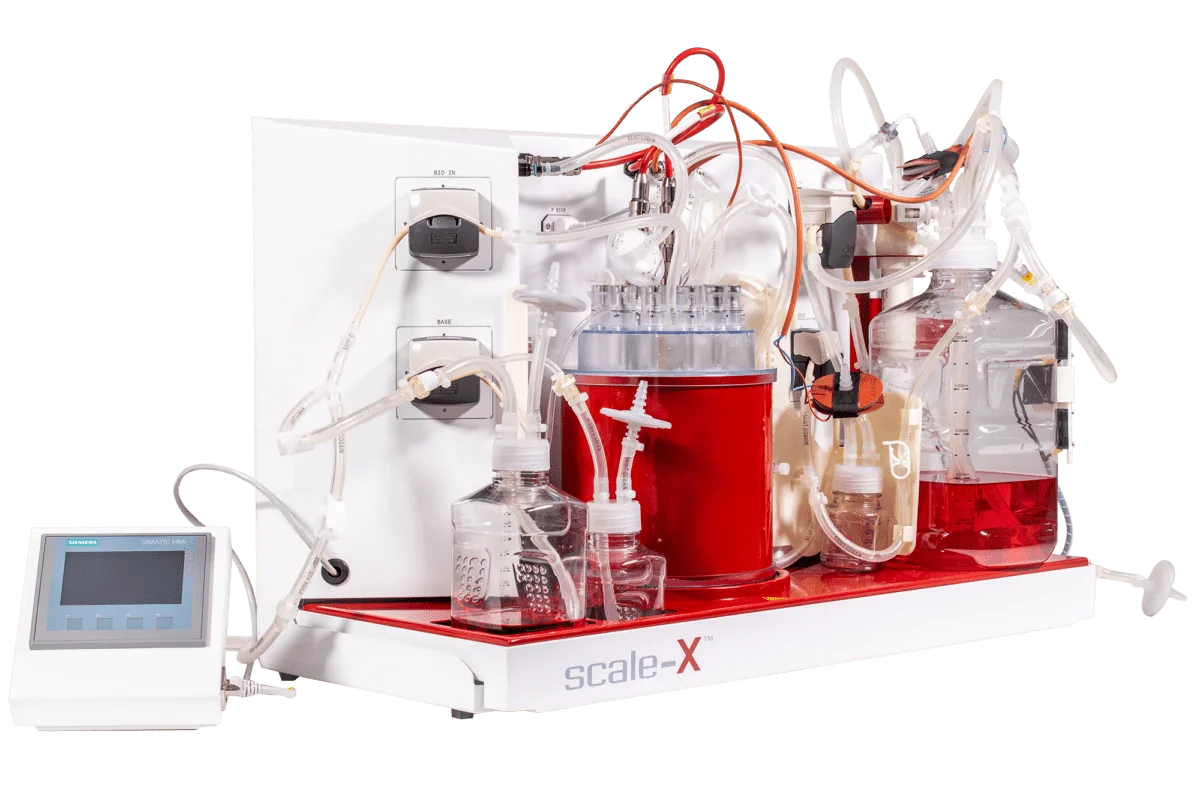

Scale-X™ carbo system

Intermediate-scale for clinical & commercial production

The scale-X™ carbo system is a GMP-compatible solution for process development, clinical and commercial production. It features a structured-fixed bed bioreactor and in-line TFF concentration automated through a centralized interface. This intermediate-scale enables to bridge the gap between R&D and commercial production offering high productivity in a low footprint with scalable processing.

Scale-X™ hydro

A small-scale R&D solution

The scale-X™ hydro is a small-scale system designed for rapid proof-of-concept and early-stage process development. Its single-use structured fixed-bed bioreactor features 2.4 m2 surface for cell growth.

This reliable automated small-scale solution offers direct process transfer opportunity from 2D technologies. It also facilitates early process optimization via rapid improvement of key process parameters within a reduced footprint.