Mixed4

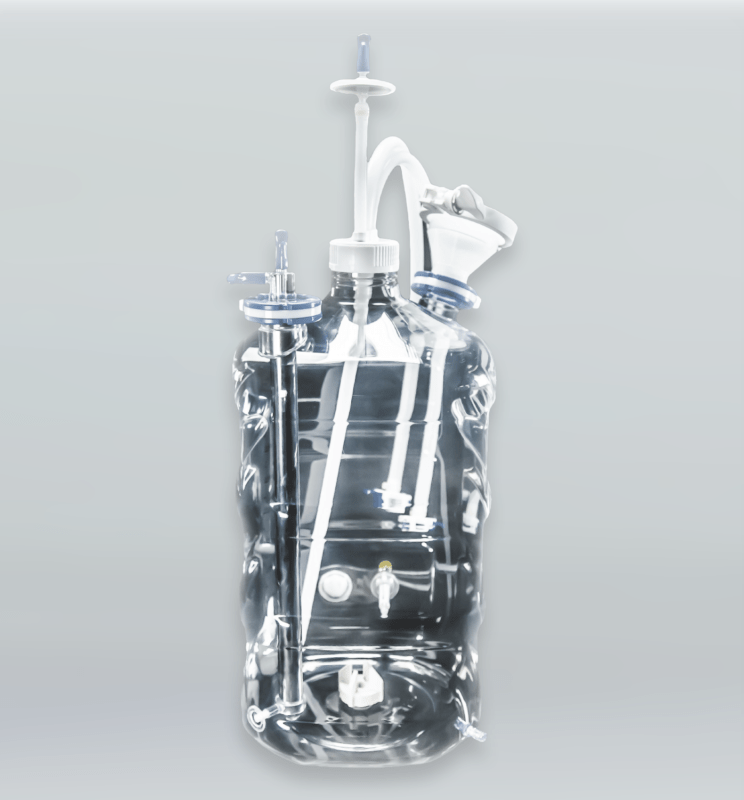

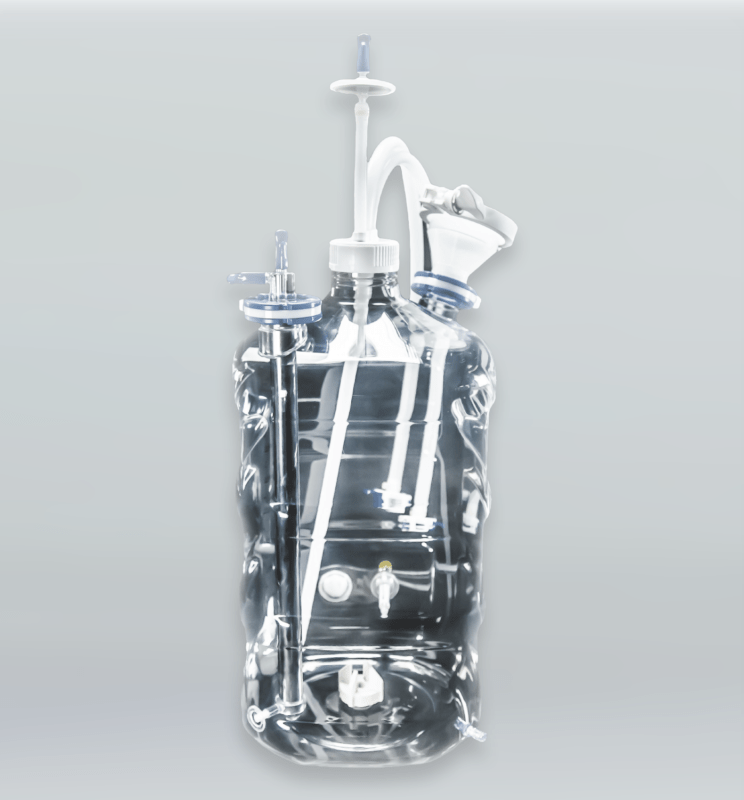

Mixed4Sure™’ Bottom Mount is an aseptic, closed-system mixing platform that offers low shear and vigorous mixing. Available in several volumes and custom configurations, enabling it to be used in a variety of mixing steps.

Materials

- PharmaTainerTM: Polycarbonate (PC) or Polyethylene Tetraphthalate (PET)

- Cap2v8®: Polypropylene (PP)

- Last Drop™ dip tube: Polypropylene (PP)

- Impeller : PEEK & Polyphenylsulfone (PPSU)

- Powder Funnel Port: Polycarbonate

Packaging

- Double-bagged and labelled in an ISO Class 7 Cleanroom

Sterilization

- Gamma radiation compatible (@50kGys)

- Sterility assurance level 10-6

Applications

- Buffer & media preparation

- Ultrafiltration/diafiltration

- Resuspension/homogenization

- Compounding

RC-40

One RC-40 system enables a single operator to complete a full roller bottle tissue culture protocol – seeding, media change, trypsinisation and harvest – for an equivalent of 200 standard roller bottles in less than two hours.

Specifications

Dimensions

- 1 98m High

- 0 95m Wide

- 0 71m Deep

Weight

- Machine only — 76Kg

- With packs loaded and 40L media — 132Kg

- With 40L media and Battery Backup — 144Kg

- Shipping weight — 110Kg

Rotor Speed

Delivery Accuracy

Power Supply

- Voltage – 90 to 264V ac

- Frequency – 47 to 63Hz

- Current – 5A

Environment

- Temperature — 0 to 40 deg _C

- Humidity — 0 to 95% RH, non-condensing

Cap2v8 Bottle Solutions

SaniSure® Cap2v8® (say “captivate”), was designed to capture, store and transfer high-purity fluid in a way that is unique to the single-use market. This product was created to solve a problem that you, our customers, had identified as preventing you from successfully making your product.

All Cap2v8 products incorporate the Cap2v8 cap – a one-piece molded tube-and-cap system that provides for aseptic transfer, storage and sampling for media bottles, glass bottles, centrifuge tubes and shaker flasks. In addition, we provide a wide array of custom bottle solutions to solve even the most demanding problems.

The molded design of the Cap2v8 assembly creates a closed sterile system that protects product integrity and provides an aseptic seal for high-purity biologicals, reducing the possibility of contamination and product loss often associated with manual processes and designs. A Cap2v8 bottle assembly reduces your labor and installation time, eliminates cleaning validation and helps you produce a more cost-effective operation.