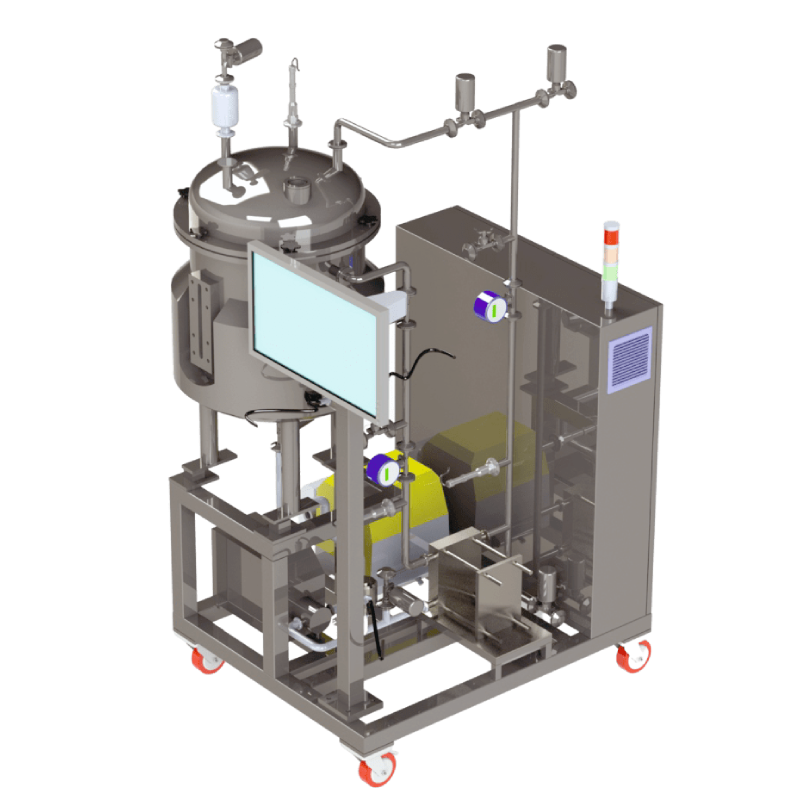

The NXT TFF System by PharmNXT Biotech is a highly efficient and automated system designed for ultrafiltration/diafiltration (UF/DF) processes. It offers a wide capacity range, from 20L to 500L, making it suitable for various batch volumes. With its compact design and low hold-up volume, it can accommodate cassettes with surface areas ranging from 0.5 to 2.5 m2. The system is known for its operational automation, enabling quick and easy flow kit changeouts and maximizing batch turnaround time. It combines hardware, a control system, and single-use flow kits to create a user-friendly and reliable system. The NXT TFF System is ideal for processing monoclonal antibodies, recombinant proteins, and vaccines, with single-use sensors providing comprehensive monitoring and process control capabilities.

The control unit uses a simple, user-friendly interface via the touchscreen for data input and programming commands. The system is shielded from unauthorized access with password protection (four levels), and all events and actions (alarms, process steps, manual commands, etc.) are recorded in accordance with cGMP guidelines. The program allows you to operate the system manually or automatically.

The NXT TFF System by PharmNXT Biotech offers several advantages for TFF (ultrafiltration/diafiltration) applications:

Cell harvesting/clarification

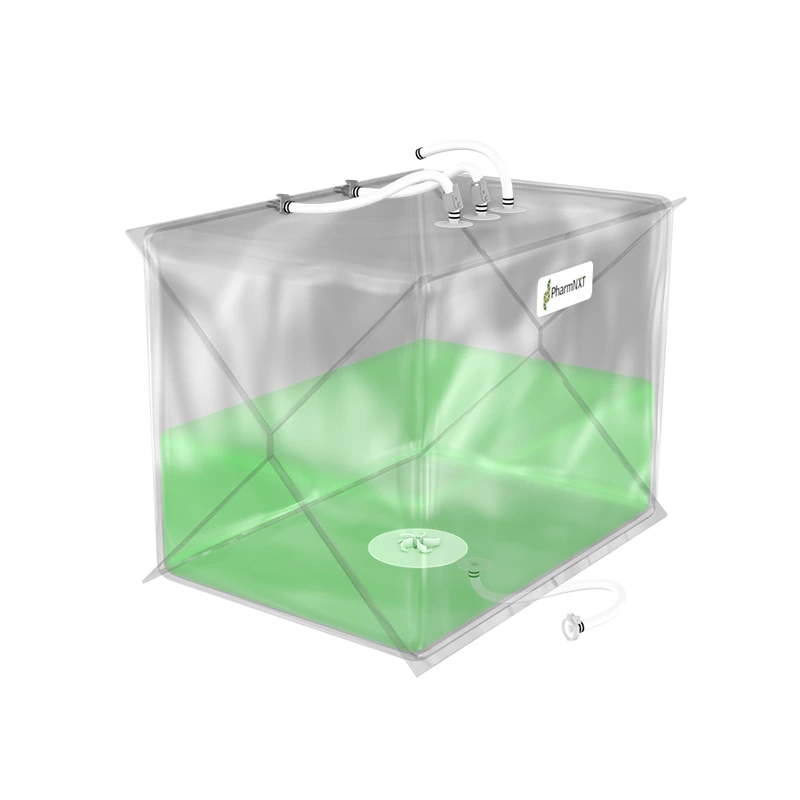

TFF processes require a tank to feed the filter and to collect retentate. If you’re running a tangential-flow filtration system, you need to consider your filtration tank. From mixing to measuring and from reducing recirculation volume to communicating with the rest of the system, the tank is an integral part of the filtration process. PharmNXT Biotech offers stainless steel tanks and single-use tanks as per process requirements. Different tank volumes can be chosen for specific systems, depending on the desired process volumes. A large range of options is available, including sensors, valves, mixers, pressurized tank, cooling jackets, and hoses