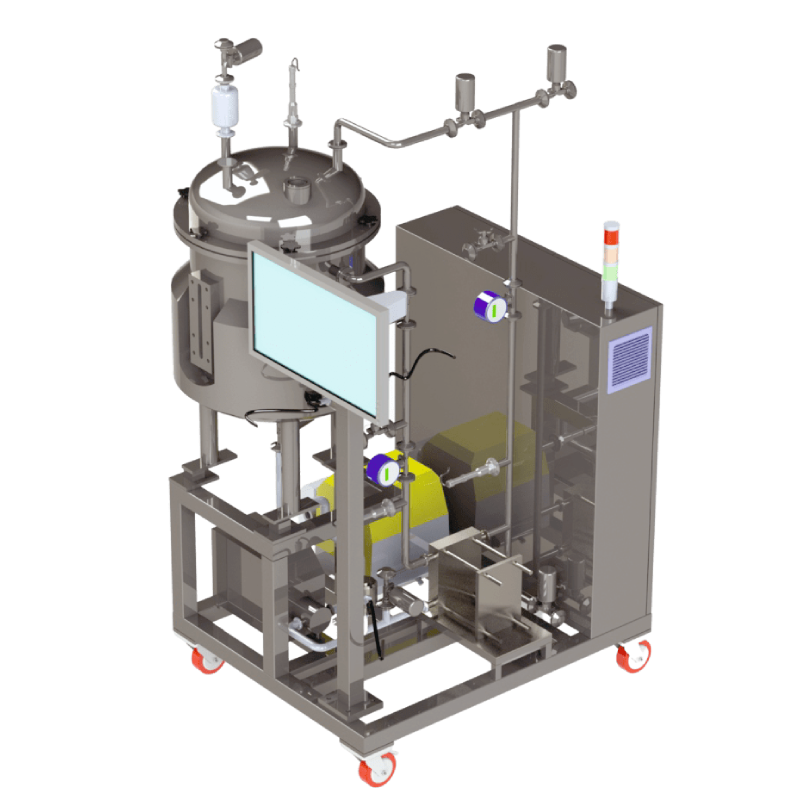

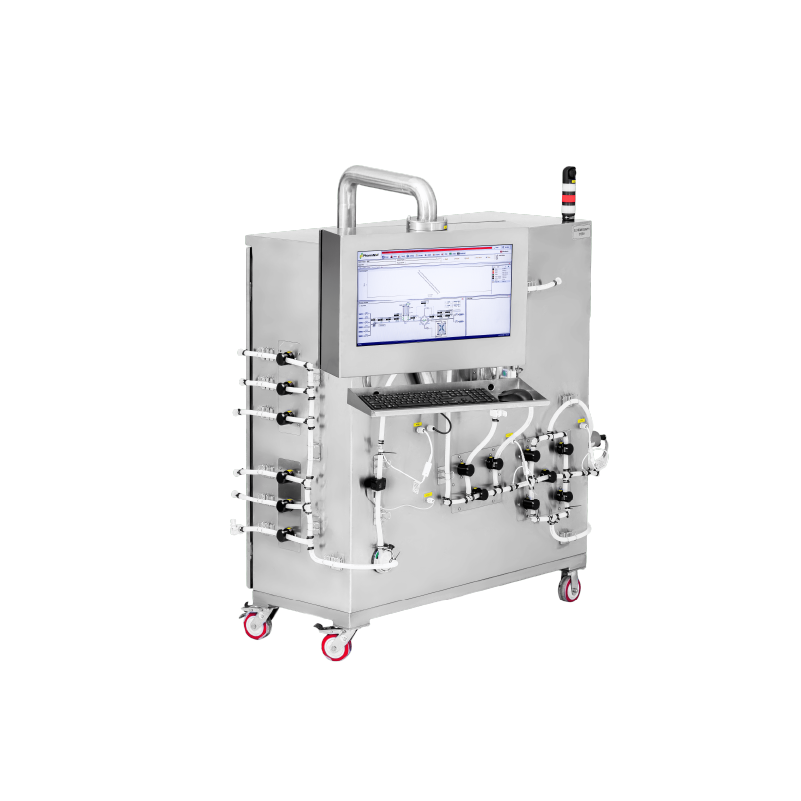

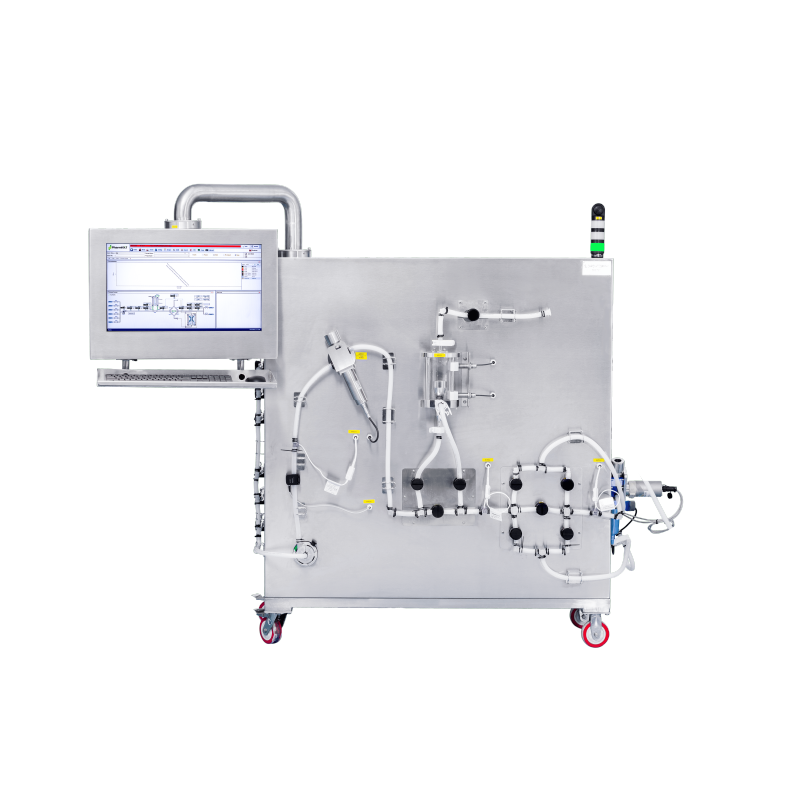

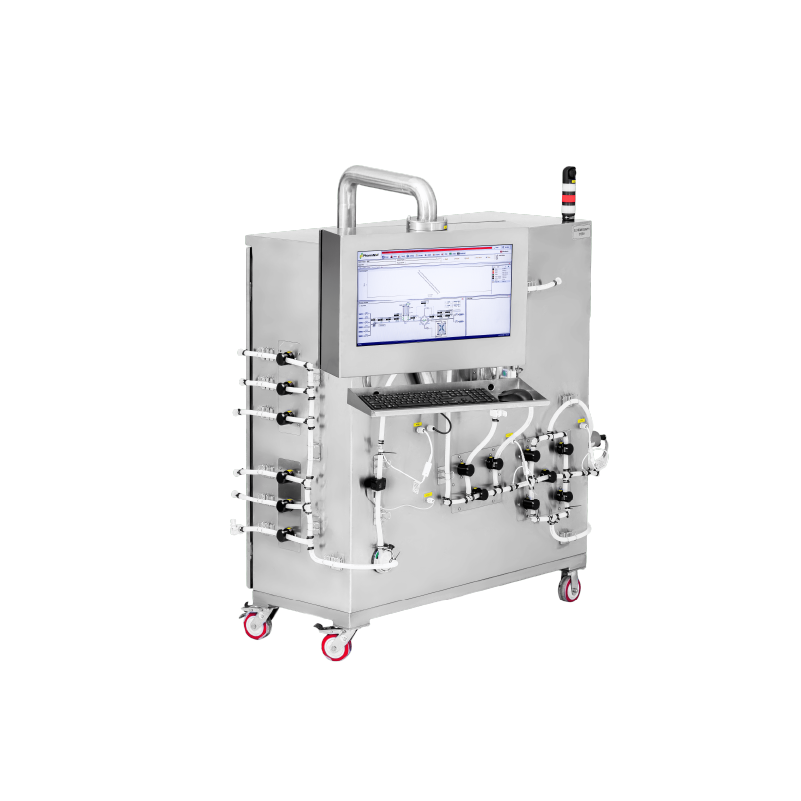

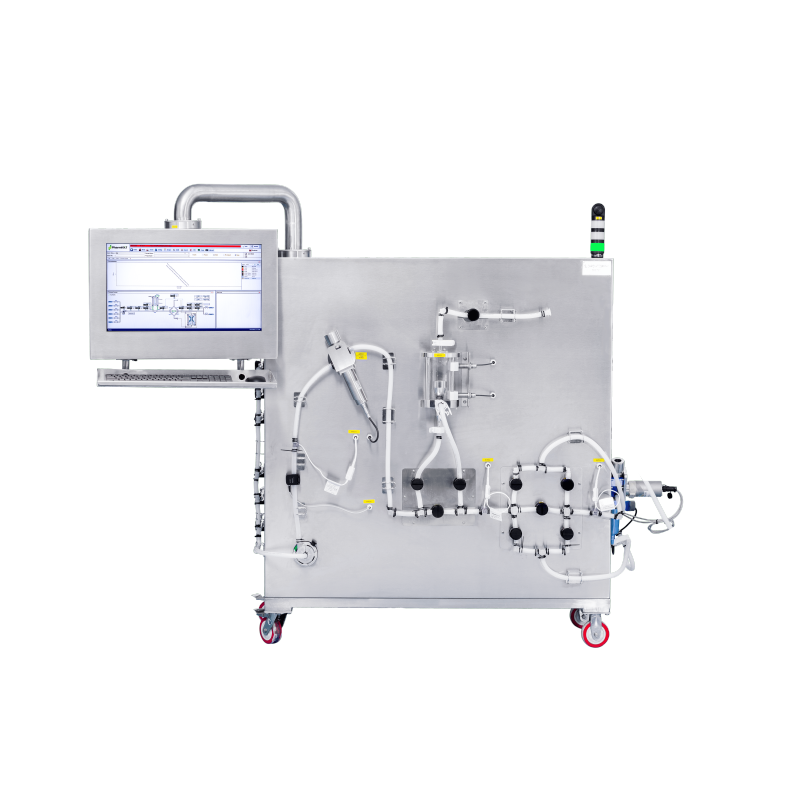

NXTchrom is a versatile range of chromatography systems that can be configured to meet various process requirements. It offers seamless integration with different options and accommodates any column diameter. The self-contained design incorporates pumps, valves, and instruments into a single system, conveniently housed on a sturdy stainless steel frame. The system is easy to operate, thanks to the user-friendly touchscreen interface and its closed construction design allows for easy connection to the plant drain. With NXTchrom, you can efficiently carry out chromatography processes with reliability and ease.

The control unit uses a simple, user-friendly interface via the touchscreen for data input and programming commands. The system is shielded from unauthorized access with password protection (four levels), and all events and actions (alarms, process steps, manual commands, etc.) are recorded in accordance with cGMP guidelines. The program allows you to operate the system manually or automatically.

The automatic mode has:

Full trend review, trend analysis, and printing from the system are all standard. Data export and configurable interfacing to external software are also included.

The NXTchrom system is fully equipped with a second pump and flowmeter adapted to the dilution ratio required for the application. A conductivity probe installed after the pumps ensures gradient or inline dilution with conductivity compensation. Highly accurate instruments and pumps lead to a maximum flow rate deviation of 1% at the system’s nominal flow rate.

The platform design allows easy customization of the process chromatography system. One or more systems that meet your precise process requirements can be produced by choosing from the required options. You can choose from a variety of sensors and specify the number of valves and ports you need.

The NXTchrom system operates with a wide range of column diameters and process flow rates, making it easy for system designers to select the appropriate system category for gradient or isocratic applications. The application ranges of the system categories overlap, meaning that one or more systems can handle specific requirements in certain situations.

It can be used for multiple flow rates and other column diameter ranges, and therefore, it will remain useful for different processes and process conditions and for future applications.

| Description | Specification |

| Piping ID | 1⁄2 Inch (Half Inch), SS316L (1.4404) |

| Maximum Operating Flow Rate | 600LPH (Overall) |

| Minimum Operating Flow Rate | 15 LPH (Overall) |

| Control Mode | Flow Control Mode + Conductivity |

| Pump | 2 Nos, Quatraflow (QF1200S) |

| pH Monitor & Sensor | 2 Nos, Mettler Toledo / Optek / E&H Conducta |

| Conductivity Monitor and Sensor | 2 Nos, Mettler Toledo / Optek / E&H Conducta |

| Flow Meter | 1 Nos, Mass, E&H / Emerson (Rosemount) |

| Pressure Sensor | 2 Nos, Flush, E&H / Keller |

| UV | 1 No, Dual Wavelength, Optek / E&H Conducta |

| Temperature Sensor | Integrated in conductivity sensor |

| Maximum Operating Pressure | 6 barg (at ambient Temperature) |

| Air Sensor | 2 (Before Inlet and Pre-Column) |

| Number of Inlets | 4 Inlets per pump (Configurable) |

| Number of Outlets | 4 outlets (Configurable) |

| Column Connections | 1 |

| Number of Filters | Configurable to 2 (Single-Use Capsules or Filter Housing) |

| Static Mixers | Optional, GMP Static Mixer, KoFlo/equivalent |

| Heat Exchanger | Can be made available if temperature needs to be maintained |

| Automated CIP | Can be made available with 4 inlet Block Valves |

| SIP | Can be made available |

| ATEX | Can be made available |