The NXTvalve SBV (Split Butterfly Valve) is purpose-engineered to deliver safe, contained, and highly efficient powder transfer in mission-critical environments such as pharmaceutical, biopharmaceutical, and chemical manufacturing. Developed with stringent regulatory and operational demands in mind, the NXTvalve ensures that both potent and non-potent powders are transferred with maximum safety and minimal risk of cross-contamination. Designed for versatility, the NXTvalve is ideal for handling Active Pharmaceutical Ingredients (APIs), excipients, and granulated materials, offering robust performance across all major powder-handling operations. These include dispensing, filling, container loading and unloading, and reactor or vessel charging, where it acts as a reliable containment interface between transfer points.

With manual operation mode, the NXTvalve integrates seamlessly into existing process lines or new installations, supporting everything from R&D scale to full-scale commercial production. Its modular design ensures easy maintenance, repeatable performance, and long-term durability, making it a preferred solution for operators and engineers focused on process integrity, product quality, and worker safety.

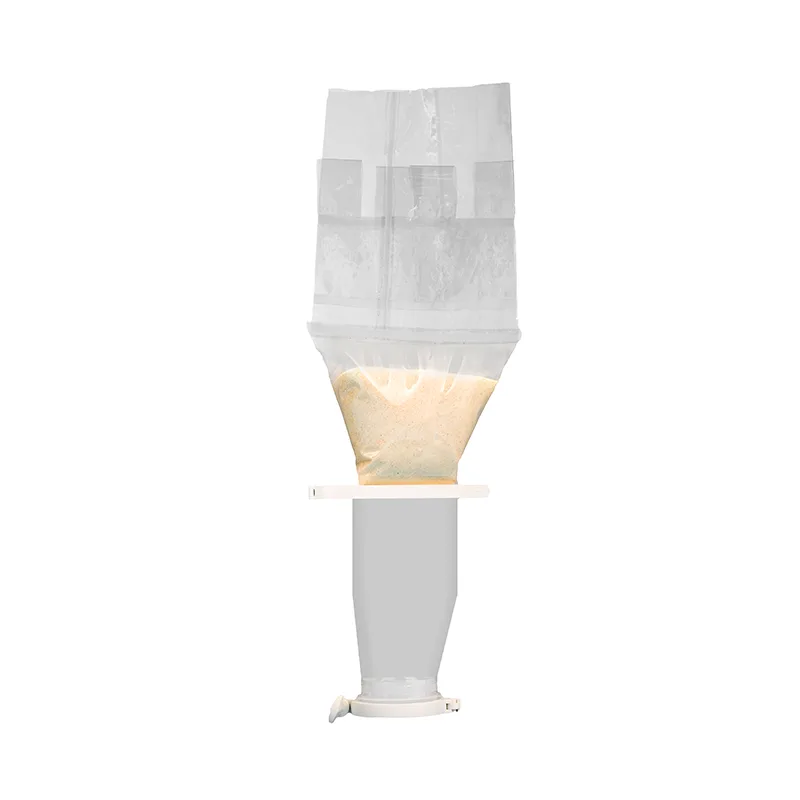

The core of the NXTvalve SBV (Split Butterfly Valve) system is its innovative two-part design, featuring an Active and Passive disc half. These two halves are engineered to mate precisely along their axis of rotation, forming a robust metal-to-metal seal at the outer edge of the discs. This unique sealing mechanism ensures high containment integrity and particle-tight closure, even under demanding conditions.

After powder transfer using the NXTValve SBV, a small amount of residue may remain on the mating surfaces, typically along the disc edge where the valve closes. This is due to powder adhering during closure and may vary based on the properties, such as particle size, moisture, or electrostatic charge. While not a system fault, it’s essential to address it as part of good GMP practice. Operators should inspect and clean both the Active and Passive units immediately after undocking using lint-free or compliant materials. This maintains hygiene, prevents cross-contamination, and supports compliance. For high-containment or sticky powders, PharmNXT Biotech offers advanced options such as anti-stick coatings, improved disc designs, and cleaning accessories to reduce residue and enhance performance.

The NXTValve SIP Passive (Active Cleaning Cap) connects to the Active valve to enable cleaning or sterilization within a sealed environment. An O-ring seal ensures a liquid-tight interface.

SIP Passive Cap for Active: With a tri-clamp connection for steam supply, SIP, or decontamination media. It can also serve as a process vent or drain when installed inverted.

SIP Passive Cleaning Cap for Active: Includes a fixed spray ball for WIP/CIP/SIP applications and can be used inverted for in-place cleaning and drainage.

The cylindrically shaped design of SIP Passive supports condensate drainage during SIP and drying cycles. The unit can be pressure rated for recirculation, flood, or high-pressure wash cycles.

Engineered with mechanical interlocks, the NXTvalve SBV ensures zero-compromise safety. This is achieved by preventing accidental exposure, enabling only secure, docked operation in full compliance with cGMP and SMEPAC guidelines.

The NXTvalve SBV offers manual and pneumatic actuation options. This provides seamless integration and operational flexibility across both small-scale and fully automated manufacturing environments.

The NXTvalve SBV ensures reliable, high-containment performance for both potent APIs and bulk excipients, combining operator safety, durability, and efficiency in every production cycle.

The NXTvalve SBV features a smart, modular design with dedicated Active and Passive halves, engineered for safe, seamless, and repeatable powder transfer in critical handling applications.

The Active Half, mounted on fixed process equipment, houses the actuation mechanism. It drives valve operations and is available in motorized or manual configurations.

The Passive Half, mounted on mobile containers, securely mates with the Active Half to form a sealed flow path, enabling high-containment powder transfer during critical operations.

The NXTvalve SBV features built-in mechanical interlocks that prevent unsafe operation, ensuring secure docking, controlled separation, and full compliance with cGMP and SMEPAC containment standards.

The NXTvalve ensures precise, repeatable alignment and secure disc locking during docking, safeguarding process integrity and enabling safe, contamination-free powder transfer.

The NXTvalve’s centralized actuation ring enables smooth, intuitive control, reducing human error and ensuring consistent, repeatable operation across all settings.

NXTvalve incorporates a modular design for easy customization, seamless integration, and future-ready performance across any setup.

Precision alignment in every docking ensures repeatability, reduces wear, and maintains the integrity of your containment process.

| Valve Parameter | Specifications |

| Product | Split Butterfly Valve Active |

| Size | 2″, 3″, 4″, 6″, 8″ |

| Containment Level | OEB 4 (1-10 req m^3) |

| Operation | Manual |

| Pressure Rating | -1 to 6 Barg |

| Temperature Rating | Upto 120°C with Sillicon & upto 210°C with FKM |

| Connection | Tri-clamp connection |

| Material of Construction (Body and disk) | Stainless Steel 316L grade (Product contact material) |

| Seat Material | Sillicon (White) or FFKM (Black) colour |

| Surface Roughness | Ra < 1.6μm |

| Bush Material | Polyether Ether Ketone (PEEK) |

| Compliance and Quality Assurance | 1) Manufactured in an ISO-accredited facility

2) Full Metrical Certification 3) Designed to GMP standards 4) Testing as per ISPE SMEPAC (under progress) 5) FDA-compliant materials |