A trusted partner at nearly three million customer locations, Ecolab is the global leader in water, hygiene and infection prevention solutions and services. With annual sales of €12 billion and more than 50,000 associates, Ecolab delivers comprehensive solutions, data-driven insights and personalised service to advance food safety, maintain clean and safe environments, optimise water and energy use, and improve operational efficiencies and sustainability for customers in the food, healthcare, hospitality, Life Sciences and industrial markets in more than 170 countries around the world.

Ecolab is committed to providing exceptional service, total plant solutions, and unsurpassed industry expertise to help you achieve your business goals. Our breadth of resources and integrated business model ensure consistency across your operations.

The Praesto AP+ platform provides a cost-effective solution for drug developers facing the dual challenge of controlling production costs while maintaining high efficacy standards. This resin series is specifically designed for the purification of a wide range of monoclonal antibodies (mAbs) and related constructs, allowing for easy implementation into existing facilities and operational parameters. Whether improving novel or legacy processes, the platform enhances manufacturing efficiencies and accelerates the timeline to clinic. By utilizing patented Jetted Technology, these resins offer uniform particle sizes that ensure enhanced performance and consistent quality.

The platform offers two distinct options to suit different processing needs:

Advantages:

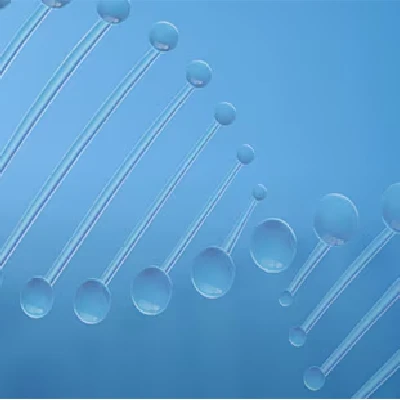

Praesto Jetted A50 is a time-tested affinity resin. It is designed for the purification of monoclonal antibodies (mAbs) and associated protein constructs. Over the last four decades, affinity chromatography has become the foundation of therapeutic medicine development. Praesto Jetted A50 resin continues that legacy by supporting various FDA-approved antibody-based therapies. Recognized as the first jetted agarose resin, it prioritizes both sustainability and productivity to meet the evolving needs of the biopharmaceutical industry. By utilizing a high-capacity 50 µm bead, Praesto Jetted A50 offers a robust dynamic binding capacity of up to 80 g/L, which helps increase product yield compared to other affinity resins.

The resin’s performance is further enhanced by its unique manufacturing process and technical features:

Praesto Jetted A50 HipH is specifically engineered to solve the stability challenges associated with purifying complex, acid-sensitive molecules like Fc-based IgGs. While these molecules are vital to therapeutic drug development, they often become unstable and aggregate at the typical elution levels of pH 3–3.5 used by standard resins, which significantly decreases product yield. This resin addresses those limitations by enabling elution at much higher levels up to pH 5, thereby enhancing monomer recovery and limiting aggregation. By mitigating protein aggregation early in the screening process, it effectively reduces the burden on downstream polishing steps, simplifying the removal of product impurities.

The technical performance of this resin is supported by several key features:

Praesto Jetted SP and Praesto Jetted Q are high-performance ion exchange (IEX) resins. They are designed to optimize selectivity and capacity for the most demanding separation requirements. As a staple in downstream purification, these resins efficiently remove a broad range of target impurities, including DNA, host cell proteins (HCPs), viruses, and leached Protein A. Both the SP and Q variants are engineered with identical chemical properties across different particle sizes. Hence, they offer tunable performance that allows process engineers to balance capacity, resolution, and flow rate according to specific molecule needs. This robust design supports seamless process scalability while providing the chemical and physical stability necessary for a long resin lifetime and reduced long-term operational costs.

To ensure consistent quality and operational flexibility, these resins include the following features:

Agarose Highly Cross-Linked Strong Anion Exchanger, Uniform Particle Size, 35 µm

Principal Applications:

Advantages:

Our residue-free hydrogen peroxide vapor generators operate over a wide temperature and humidity range for use with cage and rack washers, incubators, lyophilizers, autoclaves and biological safety cabinets.

Whether you need to reset your workspace between projects, or manage a viral or bacterial spill, you can trust Bioquell to provide a 6-log sporicidal kill in your facility. Our bio-decontamination solutions protect your assets and research, and help your lab operate more efficiently.

Spray-and-wipe methods have their place, but are prone to human error. Was every inch of the chamber or pass-through bio-decontaminated? Bioquell solutions help reduce this doubt by bio-decontaminating exposed surfaces.

Airborne or surface bio-contaminants in a sterility testing lab can contaminate a sample, which can lead to false positives or even the need to halt production. Bioquell provides a range of options to help maintain the reliability and safety of sterility testing, and reduce the risk of false positives.

A bio-contamination event can result in a costly delay to your operations. Bioquell bio-decontamination equipment works well with restricted-access barrier systems (RABS), production and filling lines. Bioquell equipment can also be used in spaces with complex surfaces, such as fermentation vessels, where manual disinfection can be challenging.

Spray-and-wipe methods have their place, but are prone to human error. Was every single surface of the pass-through or airlock decontaminated? Bioquell solutions help reduce this doubt by bio-decontaminating all exposed surfaces.

Our residue-free hydrogen peroxide vapor generators operate over a wide temperature and humidity range for use with incubators, lyophilizers, autoclaves, isolator systems, and restricted-access barrier systems (RABS).

Cleanroom expertise is crucial for cell and gene therapy production—and cleanrooms are Ecolab’s specialty. Our cleaning and disinfection innovations put biopharmaceutical manufacturing companies at the forefront of compliance, product safety and operational excellence.

Ecolab offers chemistry that is proven to meet the sensitive and rigorous demands of cell and gene therapy manufacturing. Our portfolio of cleaning and advanced contamination control products is supported by proactive service and technical expertise. When you partner with Ecolab, you’ll be assured and confident about risk management.

By using Ecolab’s Bioquell Hydrogen Peroxide Vapor systems, you achieve even more than complete surface decontamination. You can also ensure complete compliance to the laws and regulations within your country and most others around the world. We have built our business around one goal: to be the decontamination solution for any company from a start-up enterprise to a global corporation.

Ecolab delivers a comprehensive portfolio of end-to-end cleaning and disinfection solutions, including sterile IPA and sterile ethanol, that are tailored to your specific applications and goals. Review our full Cleanroom Catalog or visit our Cleanroom Program page.

The unique composition of ingredients used in the personal care and cosmetic industry require unique cleaning products and solutions. Ecolab’s comprehensive range of cleaners, sanitizers and additives are specially formulated for the range of difficult soils encountered in the manufacturing process, including pigments, emulsions, waxes and gels.

By using Ecolab’s Bioquell Hydrogen Peroxide Vapor systems, you achieve even more than complete surface decontamination. You can also ensure complete compliance to the laws and regulations within your country and most others around the world. We have built our business around one goal: to be the decontamination solution for any company from a start-up enterprise to a global corporation.

Ecolab delivers a comprehensive portfolio of end-to-end cleaning and disinfection solutions, including sterile IPA and sterile ethanol, that are tailored to your specific applications and goals. Review our full Cleanroom Catalog or visit our Cleanroom Program page.

Over 85 years of diverse industry experience, our commitment to develop innovative boiler water treatment technologies continues today. Boiler water chemical treatment coupled with 3D TRASAR™ technology provides comprehensive boiler water treatment solution mitigating scale and corrosion of the boiler system. Remote monitoring by the Ecolab Global Intelligence Center further allows you to focus on profitability of your operations. Connect today with our sales engineers and improve operations of your boiler system.

Pure water is a central component of operations in every industry, from manufacturing environments to university buildings to hospitals and everything in-between. To achieve your precise specifications and goals pertaining to water, you need a partner with trusted service and solutions expertise.

Nalco Water Purity Solutions’ capabilities in water purification technologies help to solve performance gaps, provide strategic insights, and ensure system monitoring, leading to uninterrupted performance.

Contact us for assistance in setting up service or selecting the right industrial water treatment system.

Our residue-free hydrogen peroxide vapor generators operate over a wide temperature and humidity range for use with cage and rack washers, incubators, lyophilizers, autoclaves and biological safety cabinets.

Whether you need to reset your workspace between projects, or manage a viral or bacterial spill, you can trust Bioquell to provide a 6-log sporicidal kill in your facility. Our bio-decontamination solutions protect your assets and research, and help your lab operate more efficiently.

Spray-and-wipe methods have their place, but are prone to human error. Was every inch of the chamber or pass-through bio-decontaminated? Bioquell solutions help reduce this doubt by bio-decontaminating exposed surfaces.

Airborne or surface bio-contaminants in a sterility testing lab can contaminate a sample, which can lead to false positives or even the need to halt production. Bioquell provides a range of options to help maintain the reliability and safety of sterility testing, and reduce the risk of false positives.

A bio-contamination event can result in a costly delay to your operations. Bioquell bio-decontamination equipment works well with restricted-access barrier systems (RABS), production and filling lines. Bioquell equipment can also be used in spaces with complex surfaces, such as fermentation vessels, where manual disinfection can be challenging.

Spray-and-wipe methods have their place, but are prone to human error. Was every single surface of the pass-through or airlock decontaminated? Bioquell solutions help reduce this doubt by bio-decontaminating all exposed surfaces.

Our residue-free hydrogen peroxide vapor generators operate over a wide temperature and humidity range for use with incubators, lyophilizers, autoclaves, isolator systems, and restricted-access barrier systems (RABS).

Cleanroom expertise is crucial for cell and gene therapy production—and cleanrooms are Ecolab’s specialty. Our cleaning and disinfection innovations put biopharmaceutical manufacturing companies at the forefront of compliance, product safety and operational excellence.

Ecolab offers chemistry that is proven to meet the sensitive and rigorous demands of cell and gene therapy manufacturing. Our portfolio of cleaning and advanced contamination control products is supported by proactive service and technical expertise. When you partner with Ecolab, you’ll be assured and confident about risk management.

Manufactured in accordance with cGMP conditions, Ecolab’s comprehensive range of cleaners additives and sanitizers provide process optimization throughout pharmaceutical manufacturing plants for clean in place (CIP) systems, clean out of place (COP) systems and manual cleaning.

Ecolab’s range of products are supported by a complete validation package including techniques for determining acceptable residual levels and analytical methods for residue quantification.

Choose from a range of cleanroom disinfectants, sporicides and biocides that are designed for rotational use to effectively control microbial contamination, including bacterial spores, in critical aseptic core cleanroom manufacturing areas.

The range allows you to choose the right rotational program for cleanroom disinfection or sanitization to meet the needs of your facility while considering factors such as efficacy, residue control, health and safety.

By using Ecolab’s Bioquell Hydrogen Peroxide Vapor systems, you achieve even more than complete surface decontamination. You can also ensure complete compliance to the laws and regulations within your country and most others around the world. We have built our business around one goal: to be the decontamination solution for any company from a start-up enterprise to a global corporation.

Ecolab offers a variety of cleanroom mopping systems and cleanroom cleaning supplies for applying the range of Klercide™ products to surfaces including floors, walls, ceilings and isolators.

Ecolab cleanroom mopping systems are compatible with the Klercide™ line of products and can enable a reduction in chemistry application times. The cleanroom equipment can be autoclaved and easily moved between rooms.

Sterile and filtered alcohols for cleanrooms that comprise a wide range and versatile ready-to-use options, including sterile isopropyl alcohol and sterile ethanol.

Sterile isopropyl alcohol products are ideal for residue removal, cleaning and disinfection of hard, non-porous surfaces in pharmaceutical manufacturing areas.

The Ecolab range of sterile presaturated and dry wipes provide an extensive choice for use on hard surfaces in controlled cleanroom environments. Our presaturated wipes come in pouch and mop formats for small and large surfaces. All cleanroom wipes are gamma irradiated and composed of low particulate, non-woven or 100% polyester material or binder-free, hydroentangled polyester/cellulose.

Choose the right wipe for your cleanroom cleaning system — from cleanroom IPA wipes for surface sanitization to low residue peroxide and neutral detergent wipes for general cleaning purposes.

The Ecolab range of cleanroom detergents and cleanroom cleaners enable high grade manufacturing areas to provide effective hard surface cleaning and cleanroom residue removal. Water for Injection can be used for rinsing purposes and dilution of disinfectant concentrations.

Over 85 years of diverse industry experience, our commitment to develop innovative boiler water treatment technologies continues today. Boiler water chemical treatment coupled with 3D TRASAR™ technology provides comprehensive boiler water treatment solution mitigating scale and corrosion of the boiler system. Remote monitoring by the Ecolab Global Intelligence Center further allows you to focus on profitability of your operations. Connect today with our sales engineers and improve operations of your boiler system.

We understand that your productivity and product quality could be impacted by your cooling water system. Industrial cooling towers and closed loop efficiency can be adversely affected by corrosion, scaling, fouling and biological contamination. Nalco Water offers a full array of cooling water treatment solutions including chemicals, equipment, automation and software, designed to safely optimize cooling system performance while conserving water and minimizing waste.

Safety is a priority both with our cooling water chemical treatment programs and the environment. 3D TRASAR™ technology for cooling water systems can help you reach your sustainability goals by reducing water and energy use and making blowdown safer for discharge.

Pure water is a central component of operations in every industry, from manufacturing environments to university buildings to hospitals and everything in-between. To achieve your precise specifications and goals pertaining to water, you need a partner with trusted service and solutions expertise.

Nalco Water Purity Solutions’ capabilities in water purification technologies help to solve performance gaps, provide strategic insights, and ensure system monitoring, leading to uninterrupted performance.

Contact us for assistance in setting up service or selecting the right industrial water treatment system.

As demands for better water stewardship increase throughout the world, so, too, will the needs for managing this precious resource in industrial operations. This includes several activities, including having a better understanding of all uses of water throughout an industrial complex and conserving water when appropriate; finding innovative ways to treat single or combined wastewater streams; as well as water reuse and recycling to improve water and energy efficiency.

Explore Nalco Water’s industrial water reuse and recycling applications and solutions to improve your profitability and environmental performance.